The Art of Sheetrock Cutting

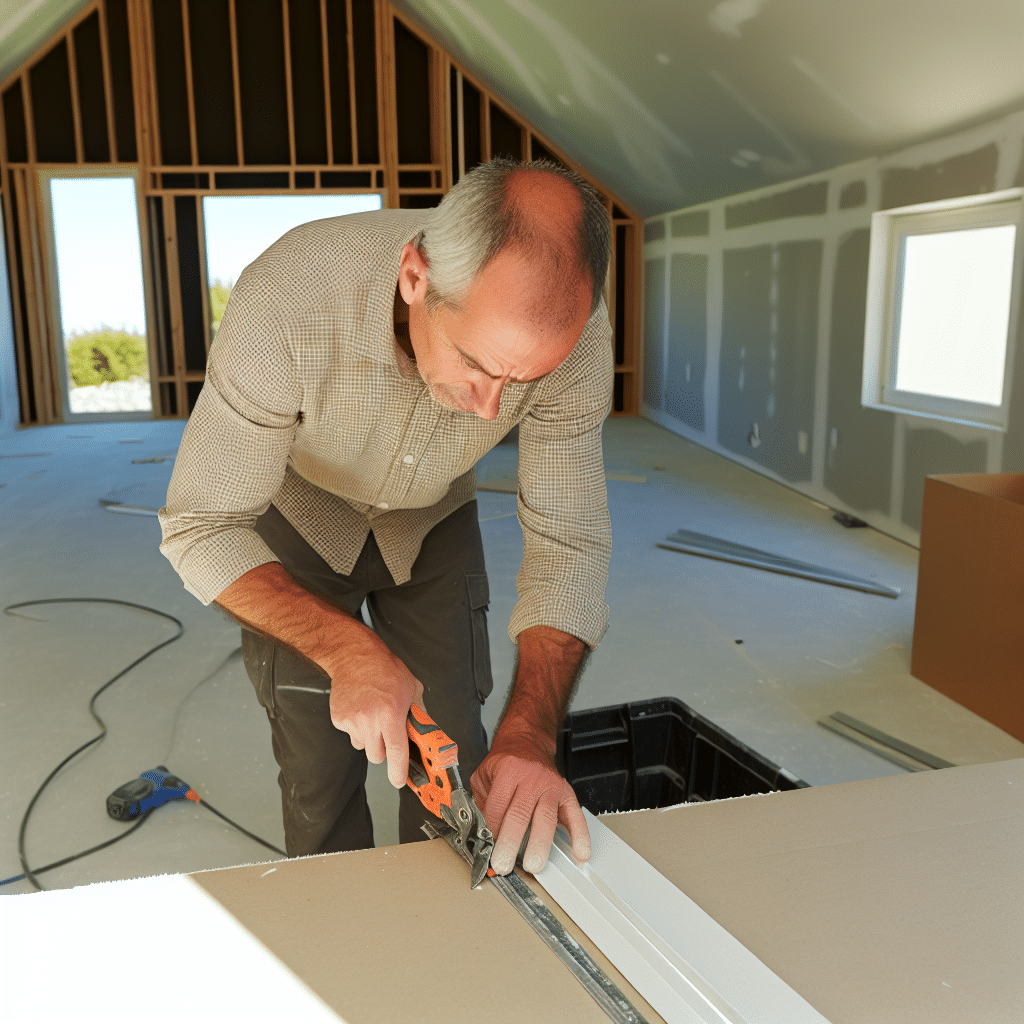

As the sun climbs high and Warwick, RI basks in the summer’s mandate for transformation, homeowners are rolling up their sleeves for much-needed renovations. Among the myriad tasks, one that stands out for its precision and impact is sheetrock cutting. The difference between haphazardly sliced boards and cleanly cut panels could mean the difference between an eyesore and a visual delight. It’s not just about aesthetics; accurate sheetrock cutting lays the groundwork for the integrity of your walls, and ultimately your home. In this first piece of our guide, we’re going to show you why cutting sheetrock properly isn’t just a necessity but a craft in its own right.

In a world where DIY has become the battle cry of the capable homeowner, it’s easy to overestimate our abilities and bite off more than we can chew—especially when tackling something like **drywall installation**. Remember, there’s no undo button when it comes to cutting material. Each slice, each measurement holds the weight of permanence. But do not be daunted; while skilled hands are a bonus, the right knowledge goes a long way. Understanding the importance of those clear-cut edges and how they fit into your project’s bigger picture is the first step toward success.

Knowing how to cut sheetrock is a feather in the cap of any home improver, a surefire way to elevate your project from amateur to expert. This is where expertise shines through—knowing, for instance, that the optimal overlap for corrugated sheetrock should be crafted with rigor, ensuring weatherproofing and a seamless fit. While tools are your tangible allies—sharp knives, straight edges, and a steadfast measuring tape—it’s your approach to these tools that will set the tone for your work. With sleeves rolled up and the clear summer day ahead, it’s time to delve deeply into the world of sheetrock, in pursuit of walls that aren’t just robust but are made with a finesse that whispers of professional quality. Let’s embark on this journey where detail is king and perfection is within your grasp.

Detailed Sheetrock Cutting Techniques

Embarking on your cutting task, it’s essential to choose the right tools and equipment carefully. A precise cut is born from the union of a sharp blade and steady guidance, making a utility knife and a T-square your trusted companions in the realm of sheetrock. Just as a pencil follows the straight edge of a ruler, your knife must adhere to the T-square’s boundary to ensure linearity. This level of precision showcases your commitment to quality and sets a professional tone throughout your project. It’s not just cutting; it’s crafting, with every incision, a step towards the perfection of your renovation.

Understanding how to navigate around common obstacles is crucial for drywall installation. Think of your electrical outlets and fixtures not as problems but as puzzles that, when solved with meticulous measurement, add to your project’s finesse. In this puzzle, your measuring tape is your best clue, promising exactness and fit that feels tailor-made. This process not only fulfills a functional purpose but also highlights your attention to detail—a hallmark of Rhode Island’s finest residential roofing crafts.

Safety is a cornerstone in all construction-related activities, especially when it involves sheetrock. Adequate personal protective gear, such as dust masks and safety goggles, is non-negotiable. They are the silent guardians that protect you from the dust and debris of your labor. Maintaining a clean workspace is equally important, as it not only prevents accidents but also serves as a testament to your methodical approach. Between the measured cuts and cautious execution, a story unfolds—one where you unfold the pages carefully, ensuring that each step is as deliberate as the last.

Finalizing Your Sheetrock Masterpiece

Tip 1:

Attention to detail is paramount when handling sheetrock, and sometimes, the smallest oversight can cause the most significant frustration. To avoid common mistakes, take a step back and take your time, ensuring each panel is meticulously measured and aligned before cutting. Remember that sheetrock can be unforgiving, and unlike many other materials, errors can be costly and time-consuming to fix. It’s not about how fast you can complete the task but how well. Your walls are the canvas, and your sheetrock work the brushstrokes that will define the outcome.

Tip 2:

Navigating around those tricky corners and edges is an art in itself—one best mastered through practice and the guidance of expert advice. Beveled and tapered edges require a keen eye to ensure a snug and seamless finish, especially in corners where any imperfection is magnified. It’s here that the experience of expert roofers, like those found at Rinaldi Roofing in Rhode Island, can serve as an invaluable reference. They resonate with the maxim that patience and precision are the true tools of an adept drywall craftsman. Your project is a personal signature, an exemplar of dedication and skill.

Tip 3:

Finally, as we wrap up this guide, it’s essential to reflect upon the journey you’ve embarked on. You’ve conquered the challenge of accurately cutting sheetrock and are on the precipice of completing a transformative home renovation. This task, while seemingly mundane, underpins the aesthetic and structural integrity of your space. Embrace the satisfaction of a job well done and take pride in the newfound knowledge and confidence this guide has instilled. Let the walls you’ve crafted stand not just as part of your home, but as monuments to your hard work and newfound expertise.

Insights From The Experts

Tip 1:

When cutting sheetrock, always use a sharp utility knife for precise cuts and score the panel multiple times to ensure a clean break. Be sure to replace blades regularly to maintain accuracy and ease of cut.

Tip 2:

Measure twice, cut once. Accurate measurements are crucial for a professional finish. Double-check your dimensions before cutting to minimize waste and guarantee a proper fit, especially around outlets and corners.

Tip 3:

For straight cuts, utilize a T-square to guide your utility knife. This not only helps keep the cut straight but also adds stability, reducing the chance of the knife slipping and causing imperfections or injuries.

Tip 4:

Consider the type of edge needed for your drywall project. For adjoining pieces, beveled edges could make the finishing process smoother, while tapered edges are better suited for corners.

Tip 5:

Wear protective gear, including safety glasses and a dust mask, to guard against sheetrock dust and debris when cutting. A clean work environment also ensures better air quality and visibility, enhancing both safety and the quality of your work.

Expert Answers to Your Sheetrock Queries

What Are The Essential Tools Needed For Cutting Sheetrock?

The key tools for cutting sheetrock are a sharp utility knife, straightedge or T-square, measuring tape, and a saw for more complex cuts. Quality, sharp blades are essential for clean, effortless cuts.

How Can I Ensure Clean Cuts When Working With Sheetrock?

Using a new blade in your utility knife will result in cleaner cuts, and always score the sheetrock multiple times before snapping for a precise break. A straightedge tool aids in maintaining linearity.

What Safety Precautions Should I Take When Cutting Sheetrock?

Always wear safety goggles to protect your eyes from dust, and use gloves to protect your hands from sharp edges. Keeping your work area clean will help prevent trips and falls.

Can I Cut Sheetrock On My Own Or Should I Hire A Professional?

While you can cut sheetrock on your own with the proper tools and knowledge, hiring a professional ensures a higher quality finish, especially for complex projects or inexperience.

What Are The Common Mistakes To Avoid When Cutting Sheetrock?

Avoid rushing the job, as this often leads to inaccurate cuts and waste. Never use dull blades, as they make cutting more difficult and increase the risk of accidents.